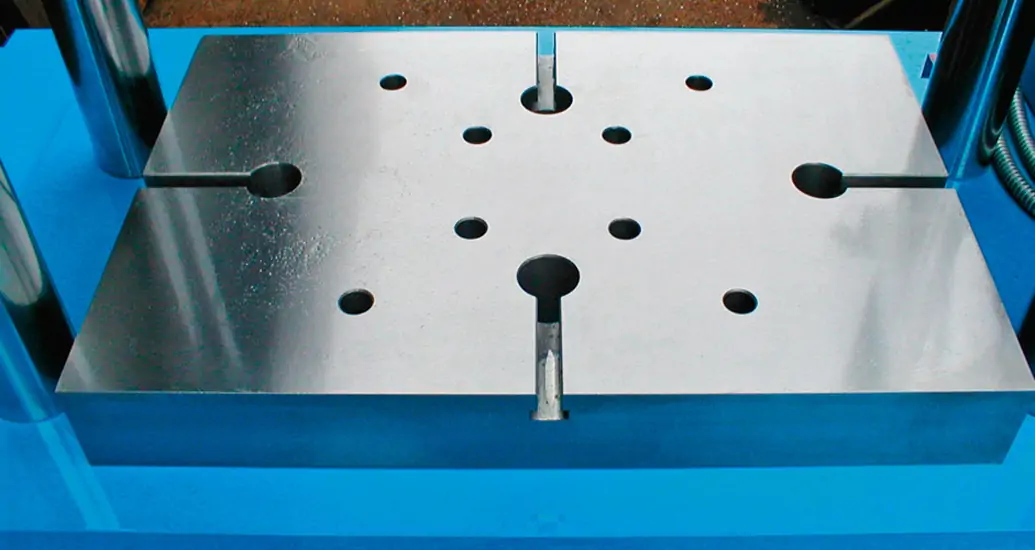

Presses designed for operations with precision pressing tools while the moving work table is guided with 4 columns. They can be equipped with hydraulic system for deep drawing operations or with an opening in the lower work table for trimming operations (Al-castings).

Available in different designs, made in accordance with your order and specific technical requirements in respect of the pressing force (5t – 630t) , cylinder stroke, size and shape of the work bench, operating speeds, extra equipment and accessories, control mode, etc.

Application: pressing, bending, punching, deep drawing, trimming of castings, …

Control: electro; PLC processor, with possibility for adjustment of all nedeed operation parameters as well as the complete process automation.